Products

-

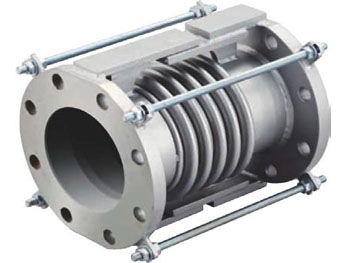

AXIAL BELLOWS:

This is the simplest assembly in family of expansion joint. It consists of a bellow element with end connections. It is used for axial movement only in pipe configurations. However, it can also absorb small amounts of other two types of basic movements viz. lateral and angular Rotation.

The expansion joint should not be expected to control the movement of the pipe. If the piping analysis shows that the expansion joint must accept axial compression, then the piping must be guided and constrained so that only that movement will occur. This expansion joint will not resist any deflections with any force other than the resistance of the bellows, which is a function of the spring rate times the deflection amount. It is incapable of resisting the pressure thrust along its axis, which is the product of the pressure times the effective, or cross sectional, area of the bellows.

- UNIVERSAL BELLOWS:

Universal expansion joints contain two bellows with multiple convolutions joined by a center pipe or spool. These joints, also known as double or tandem bellows expansion joints are used for the purpose of absorbing any combination of axial, lateral, or angular movements in a piping system. When lateral movements are too excessive for a single axial expansion joint to accommodate or when there is a limitation on the amount of lateral forces allowed on the connecting piping or equipment, universal expansion joints are installed to accommodate these movements. Universal types can be supplied with or without tie rods. Tie rods connect the ends of the unit to each other and restrain the pressure thrust load. This unit is normally not expected to accept any externally applied axial deflections. The tie rods usually come in sets of two or more, equally distributed around the circumference of the expansion joint.

- HINGED BELLOWS:

Hinged expansion joints are usually used in sets of 2 or 3 elements to absorb lateral deflection in one or more directions in a single plane. Each element of the assembly is subject to pure angular rotation by its hinge pin. Each pair of bellow element connected by a segment of pipe will act in unison to absorb lateral deflection in much the same way as universal joint in a single plane. The hinges are designed strong enough to take the axial pressure thrust and also to transmit the piping deflections in a plane perpendicular to the plane of hinge rotation. Hinged Bellow also have added benefits of Positive Control over the Movements, Eliminates, Pressure Thrust Force, Transmits External loads, Prevents torsion on Bellow and are the most Efficient in absorbing of Thermal Deflection.

- GIMBAL BELLOWS:

A gimbal expansion joint is designed to permit angular rotation in any plane by using two pairs of hinges attached to a common floating gimbal ring/box. Gimbal ring/box, hinge arms and pins are designed to restrain pressure thrust of the bellows and any extraneous forces where applicable. Typical gimbal systems consist of “(2) gimbal expansion joints” or “(2) gimbal and (1) hinge expansion joints”

Advantages of Gimbal Expansion Joints: Just as hinged expansion joints offer great advantages in single plane applications, gimbal expansion joints are designed to offer similar advantages in multi-plane systems. Since gimbal expansion joints are not restricted to single plane systems, they have greater flexibility of usage.

- ELBOW TYPE PRESSURE BALANCE:

This type of expansion joint is really a combination of several types. Its purpose is to retain and balance the pressure thrust so that main anchoring of the pipe or adjacent equipment is not required, and forces and movements on attachment flanges of delicate equipment, such as turbines, are kept to acceptably low levels. The deflections to be accepted are handled by the proper type of pipe expansion joint, which normally, is a tied universal type to accept lateral movements. However, the pressure balanced elbow is usually required because axial deflections are also present. In order to accept these movements, a bellows is added beyond the elbow with the same cross-sectional area as the ones in the universal section. These bellows can be also used at the bends of the piping or change in direction of piping, where adequate support or main anchors is not possible.

The axial spring rate of the expansion joint is the sum total of spring rates of line bellows and the balancing bellow.

- S.S. FLEXIBLE CORRUGATED METALLIC HOSES & ASSEMBLIES:

All metal corrugated flexible hoses are made from thin gauge material with bellows type construction & supplied with S.S. 304 wire braiding. The need of all metal corrugated flexible hoses arises due to limitations of rubber, Teflon or Plastic Hoses. these hoses General used where high pressure & high temperature and corrosive materials are to be passed.

Made From SS AISI 304,321 Materials With SS 304 Single OR Double Wire Braiding. on Special Request SS AISI 316L Material Hoses are Supplied.